Precision Workholding for Large and Complex CNC Machining

When machining large, heavy, or high-value parts, workholding is a critical determinant of accuracy, productivity, and overall machining efficiency. Kurt Workholding’s extra capacity CNC vises—including the D100 machine vise, XL8 and XL6 manual vises, the XL8H and XL6H hydraulic vises, the XL6A pneumatic vise, and the PF840 self-centering vise—are engineered to deliver superior clamping force, rigidity, and repeatability across a wide range of CNC machining applications.

Designed and manufactured in the USA, these heavy-duty vises address the challenges of large part machining, high-horsepower cutting, and multi-axis CNC operations, while maintaining the precision Kurt Workholding is known for.

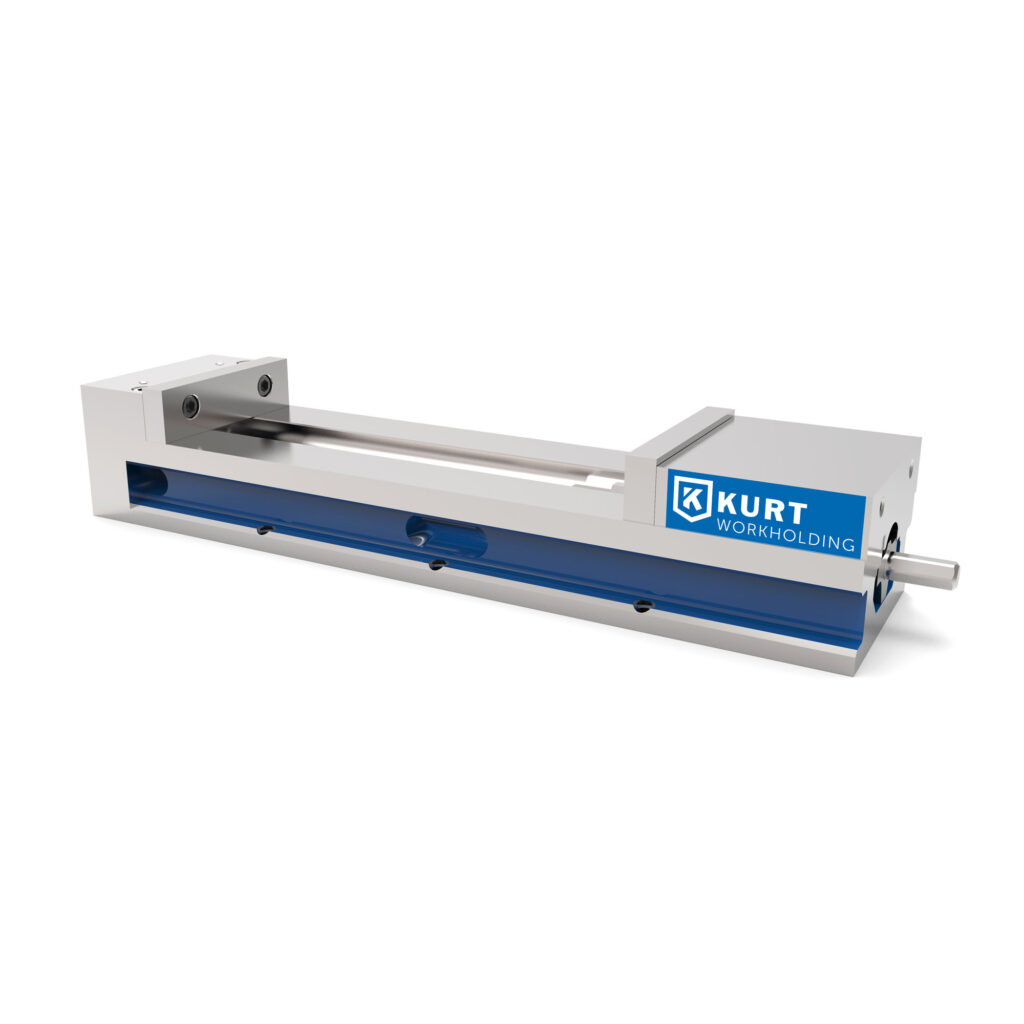

Kurt XL8 Extra Capacity Manual Vise: Maximum Capacity for Oversized Parts

The Kurt XL8 extra capacity manual vise is purpose-built for machining oversized workpieces that exceed the limits of standard CNC vises. With an 8-inch wide jaw and jaw openings approaching 29 inches and clamping forces exceeding 20,000 pounds, the XL8 provides exceptional stability during aggressive roughing and finishing operations.

Constructed from 80,000-psi ductile iron, the XL8 minimizes vibration and resists deflection under heavy loads. Kurt’s proven AngLock® technology pulls the movable jaw downward as it clamps, virtually eliminating jaw lift and ensuring the workpiece remains firmly seated throughout the machining cycle. Available in manual configurations, the XL8 is ideal for large horizontal and vertical machining centers where strength and accuracy are paramount. Also available in a reverse configuration.

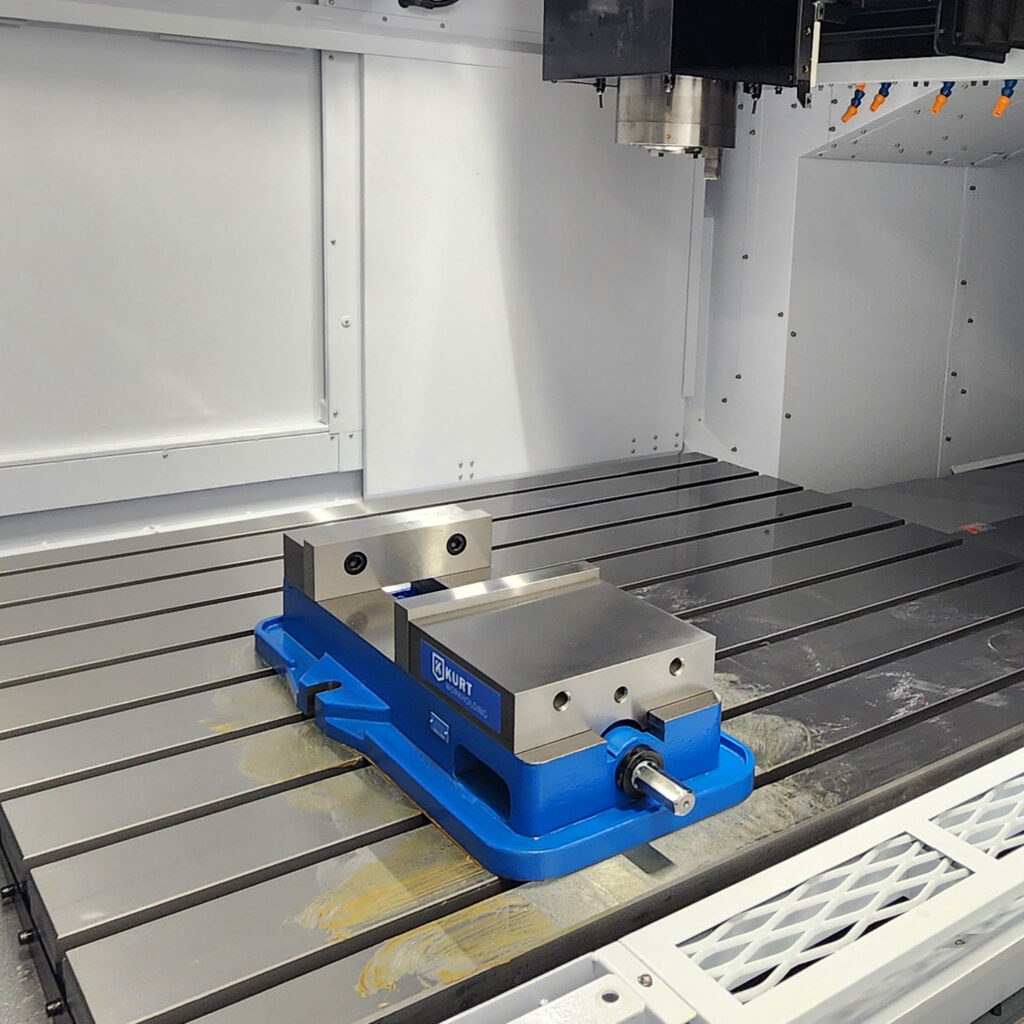

Kurt XL6 Extra Capacity Manual Vise: Power and Precision in a Smaller Footprint

The Kurt XL6 extra capacity manual vise delivers extra capacity and precision in a more compact form. With a 6-inch wide jaw openings exceeding 19 inches and clamping forces near 7,000 pounds, the XL6 is well suited for medium-to-large CNC machining applications that demand more holding capacity than traditional vises can provide.

Like the XL8, the XL6 incorporates Kurt’s AngLock design to reduce jaw lift and maintain consistent part positioning. Its smaller footprint allows multiple vises to be mounted on larger CNC machines, making it an excellent choice for flexible fixturing and modular workholding setups. Also available in a reverse configuration.

XL6H and XL8H Hydraulic Extra Capacity Vises: Consistent Clamping for Production Machining

For shops seeking repeatable, automated clamping, Kurt offers the XL6H and XL8H hydraulic extra capacity vises. These models retain the same rigid ductile iron construction and AngLock jaw geometry as the manual versions but add hydraulic actuation with a 1/4-inch stroke for consistent, hands-free operation.

Hydraulic clamping provides uniform force from part to part, reducing setup variability and supporting high-production or lights-out machining environments. The XL8H accommodates jaw openings up to 28.765 inches, while the XL6H supports openings up to 19.25 inches, making them ideal for large and intermediate-size parts in demanding CNC operations. Also available in reverse configurations.

Add the Kurt KHP3 Hydraulic pump and minimal accessories and you can create a turnkey automation setup. Learn how to automate a hydraulic CNC vise in this blog post.

XL6A Pneumatic Extra Capacity Vise: Air-Powered Efficiency and Control

The Kurt XL6A pneumatic extra capacity vise offers air-powered clamping for applications that benefit from fast, clean, and easily automated actuation. Delivering up to 5,000 pounds of clamping force, the XL6A combines pneumatic efficiency with Kurt’s AngLock technology to ensure secure, accurate part holding.

With 6-inch wide jaws and a 19.25-inch maximum jaw opening, the XL6A is well suited for high-mix machining environments, automated cells, or applications involving more delicate components where controlled clamping pressure is essential. Pneumatic operation also allows seamless integration with shop air systems for improved workflow efficiency. Also available in a reverse configuration.

Use a Kurt Filter Regulator Lubricator (FRL) and a Kurt Switch and Shop Air to get started with a turnkey pneumatic automation setup. Learn how to automate a pneumatic CNC vise in this blog post.

D100 Machining Vise: Massive Part Holding with 10-inch Wide Jaws

The D100 Machining Vise is the largest and strongest of Kurt Workholding’s general purpose vises. With a 10-inch wide and 9-3/4″ jaw opening and up to 16,163 pounds of clamping force, it has the capacity and strength to take on your highest horsepower milling cuts. It’s the most precise and rugged 10″ production vise in the world.

The D100 AngLock® vise is designed for precision part clamping on CNC machine tools and machining centers. It is ideal for running production parts where datums, flatness, and parallelism are important, and makes it easy to bore, tap, drill, and finish with high accuracy. No other manufacturer can provide the time-tested accuracy of Kurt’s AngLock® vises. Kurt’s custom engineered workholding team can also create a two-vise tower with two D100 vises bolted together and mounted vertically on a base—perfect for holding massive parts in a two-up vertical configuration.

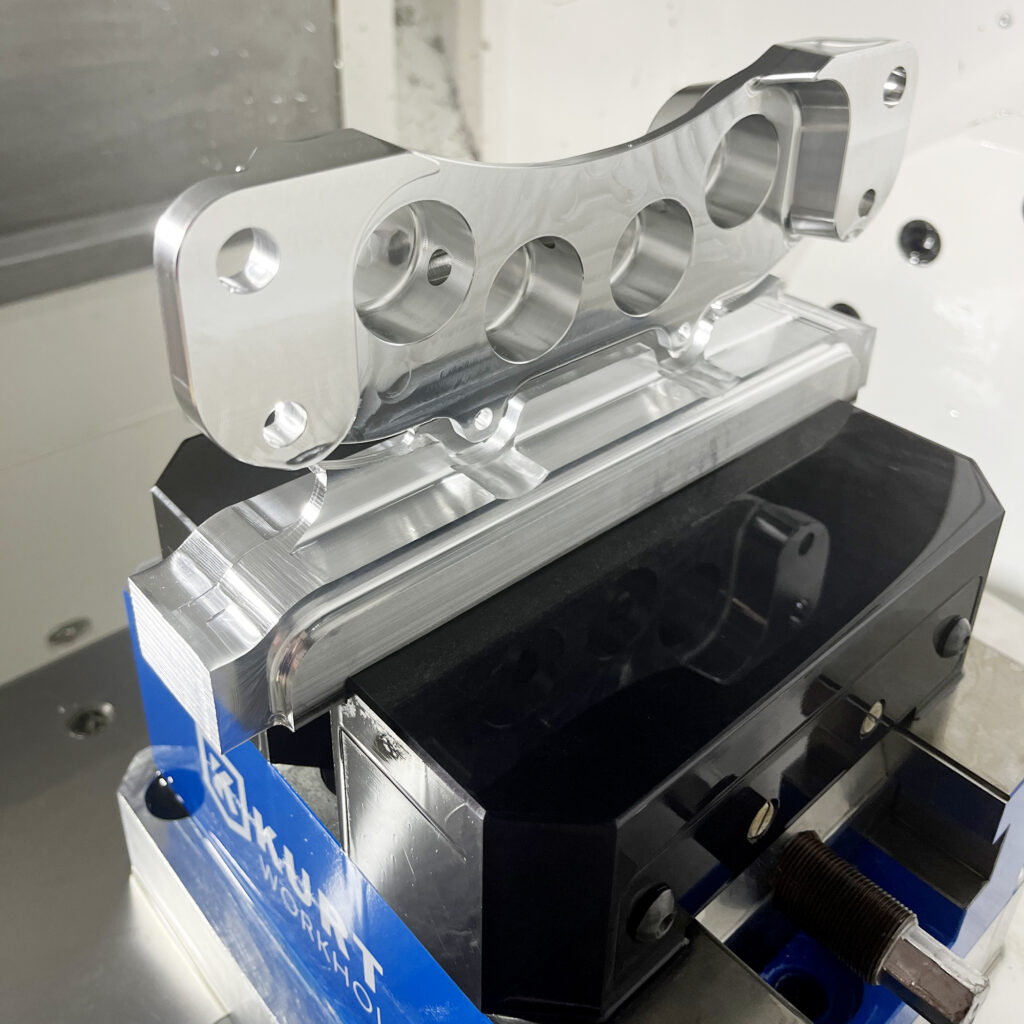

PF840 Self-Centering Vise: Faster Setup for 5-Axis CNC Machining

When you’re looking for large-part workholding but don’t have the space for a long XL-style vise, the Kurt PF840 self-centering vise is is a great option for multi-axis CNC machines. Engineered to dramatically reduce setup time while increasing repeatability, the PF840 works particularly well in 5-axis CNC machining. Featuring synchronized jaw movement, the PF840 automatically centers the workpiece on the spindle centerline, eliminating manual alignment and minimizing operator error.

With an 8-inch jaw width, the PF840 is one of the largest self-centering CNC vises available, making it well suited for aerospace, defense, and complex multi-sided machining applications. Improved tool access and consistent centering help reduce cycle times and support tighter machining tolerances.

Key Benefits by Vise Model

XL8 Manual Extra Capacity Vise

- Extremely large jaw opening for oversized parts

- Over 20,000 lbs of clamping force

- AngLock® technology minimizes jaw lift

- Ideal for heavy roughing and large CNC machines

- Also available in reverse configuration

XL6 Manual Extra Capacity Vise

- Smaller XL footprint with extended jaw capacity

- Strong, consistent clamping for mid-to-large parts

- Excellent option for multi-vise CNC setups

- Proven Kurt rigidity and precision

- Also available in reverse configuration

XL8H Hydraulic Extra Capacity Vise

- Automated hydraulic clamping for production environments

- Large jaw opening for oversized components

- Consistent clamping force across part batches

- Ideal for high-horsepower and lights-out machining

- Also available in reverse configuration

XL6H Hydraulic Extra Capacity Vise

- Hydraulic precision in a smaller extra-capacity format

- Reduced setup time and operator variability

- Excellent for repeatable CNC production work

- Rigid ductile iron construction

- Also available in reverse configuration

XL6A Pneumatic Extra Capacity Vise

- Air-powered clamping for automation-ready workflows

- Controlled clamping force for sensitive parts

- Easy integration with shop air systems

- Strong, reliable performance for high-mix machining

- Also available in reverse configuration

D100 Machining Vise

- Kurt’s largest general-purpose vise

- Ideal for large part holding in machining centers

- Maximum clamping force: 16,163 ft/lb

- 10-inch wide jaws with 9-3/4″ jaw opening

PF840 Self-Centering Vise

- Automatic centering for faster CNC setups

- Ideal for multi-axis and multi-sided machining

- Improved tool access and reduced cycle times

- High repeatability for short-run and production work

Scalable CNC Workholding for Demanding Applications

From oversized components to complex multi-axis machining, Kurt Workholding’s XL and PF series vises provide scalable, high-performance workholding solutions. Whether you need manual strength, pneumatic efficiency, hydraulic consistency, or self-centering precision, the XL6, XL8, XL6A, XL6H, XL8H, and PF840 deliver the accuracy, durability, and productivity required in today’s advanced CNC machining environments.