Custom workholding solutions.

Made for you.

Your ideas aren’t off-the-shelf. Why should your workholding be? When you want the best workholding solutions for your specific needs, let Kurt custom-build them for you. Then, get ready to experience increased throughput and lower costs.

For over 50 years, Kurt has been the industry leader in custom, high-performing horizontal, vertical, or multi-axis CNC machine workholding solutions — made to be easily integrated into new or existing automated cells and machining centers.

From tombstones to simple manual vises to dedicated hydraulic vises, Kurt has the solution for you. To create yours, contact Kurt Workholding today for a free, no-obligation evaluation of your project.

Explore Kurt’s Custom Workholding Solutions for Horizontal CNC Systems

There’s a reason Kurt is the leader in customized workholding solutions for horizontal CNC machining centers. Our dedication to excellence is in everything we deliver.

Examples of our custom solutions:

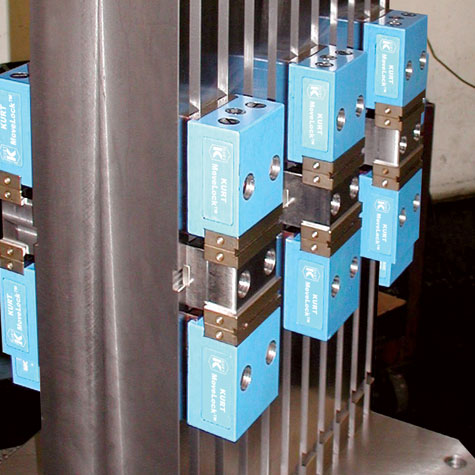

- High-density, DoubleLock vise setups capable of holding 18 parts for aerospace machining operations

- Two-sided tombstones with six MoveLock clamping stations to accommodate different part sizes

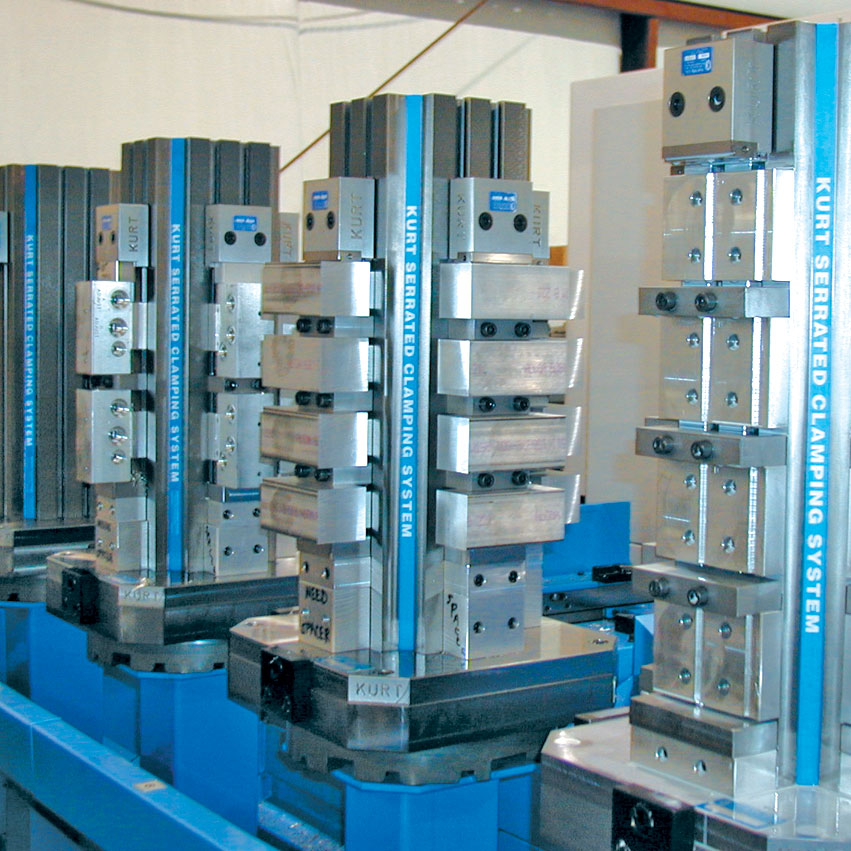

- Serrated double-station vise towers on palletized machining centers for round-the-clock production and many other highly-specialized custom products

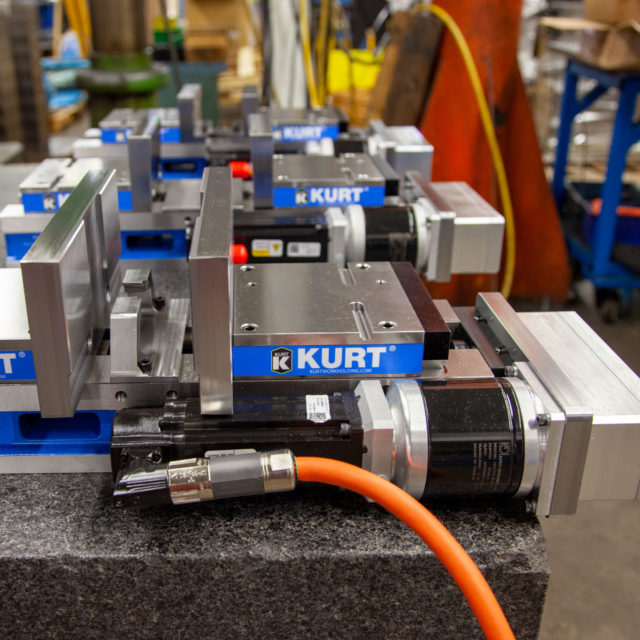

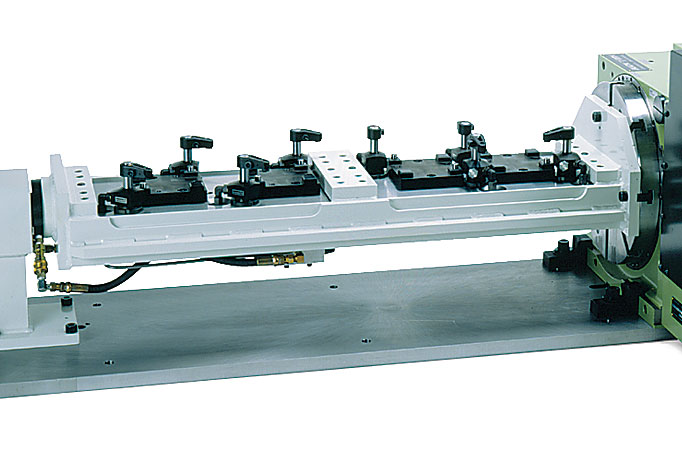

Solution: Two-sided tombstone with six MoveLock clamping stations handle wide range of part sizes.

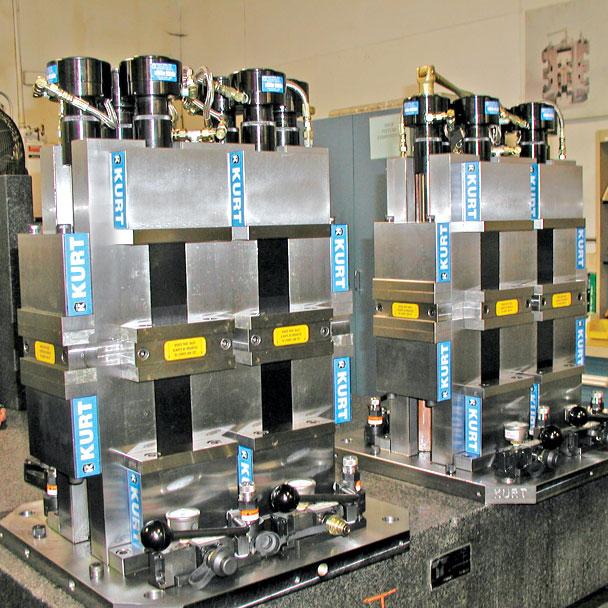

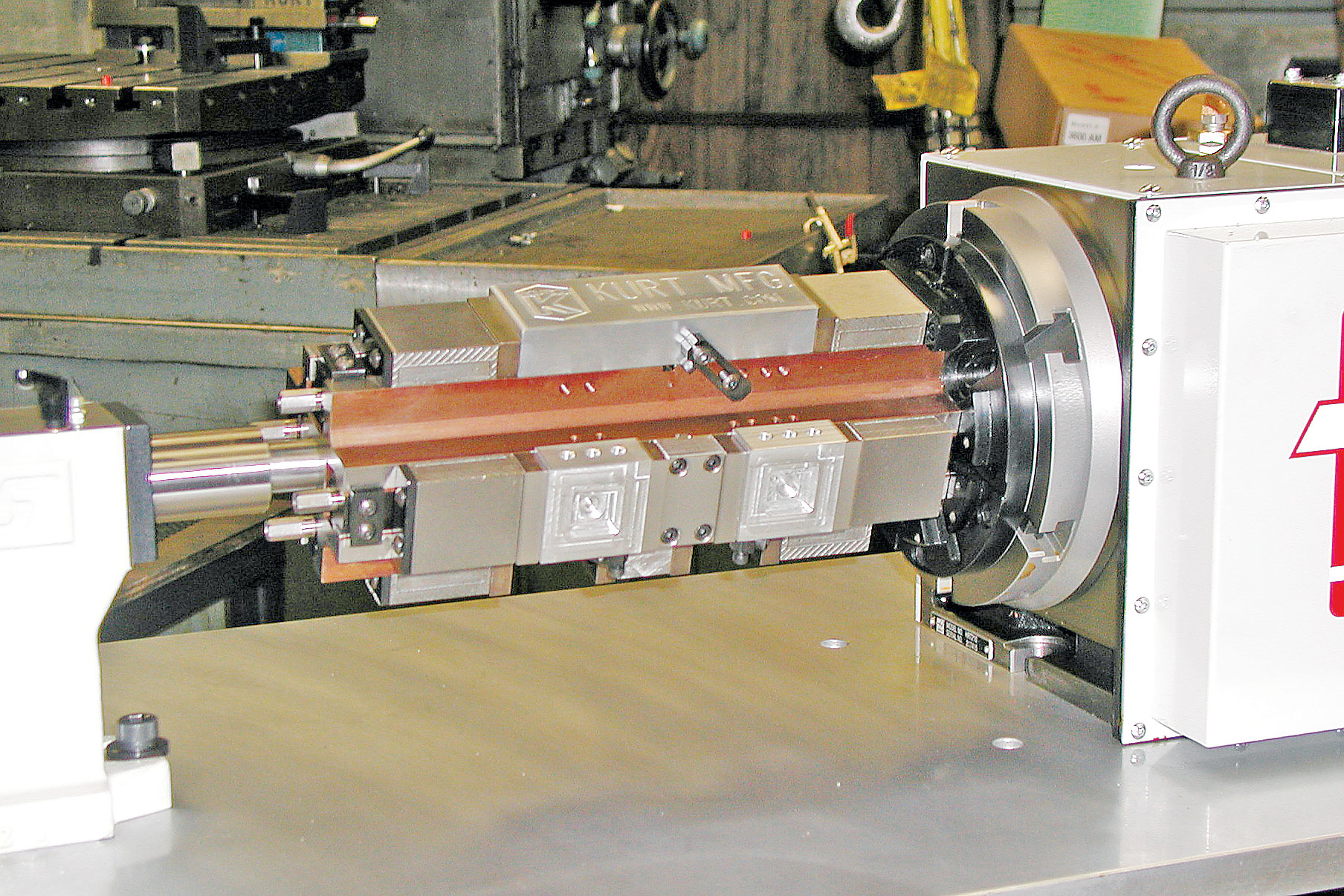

Solution: High density DoubleLock vise setup holds 18 parts for precision machining.

Solution: D100 movable and stationary jaws integrated onto a tower.

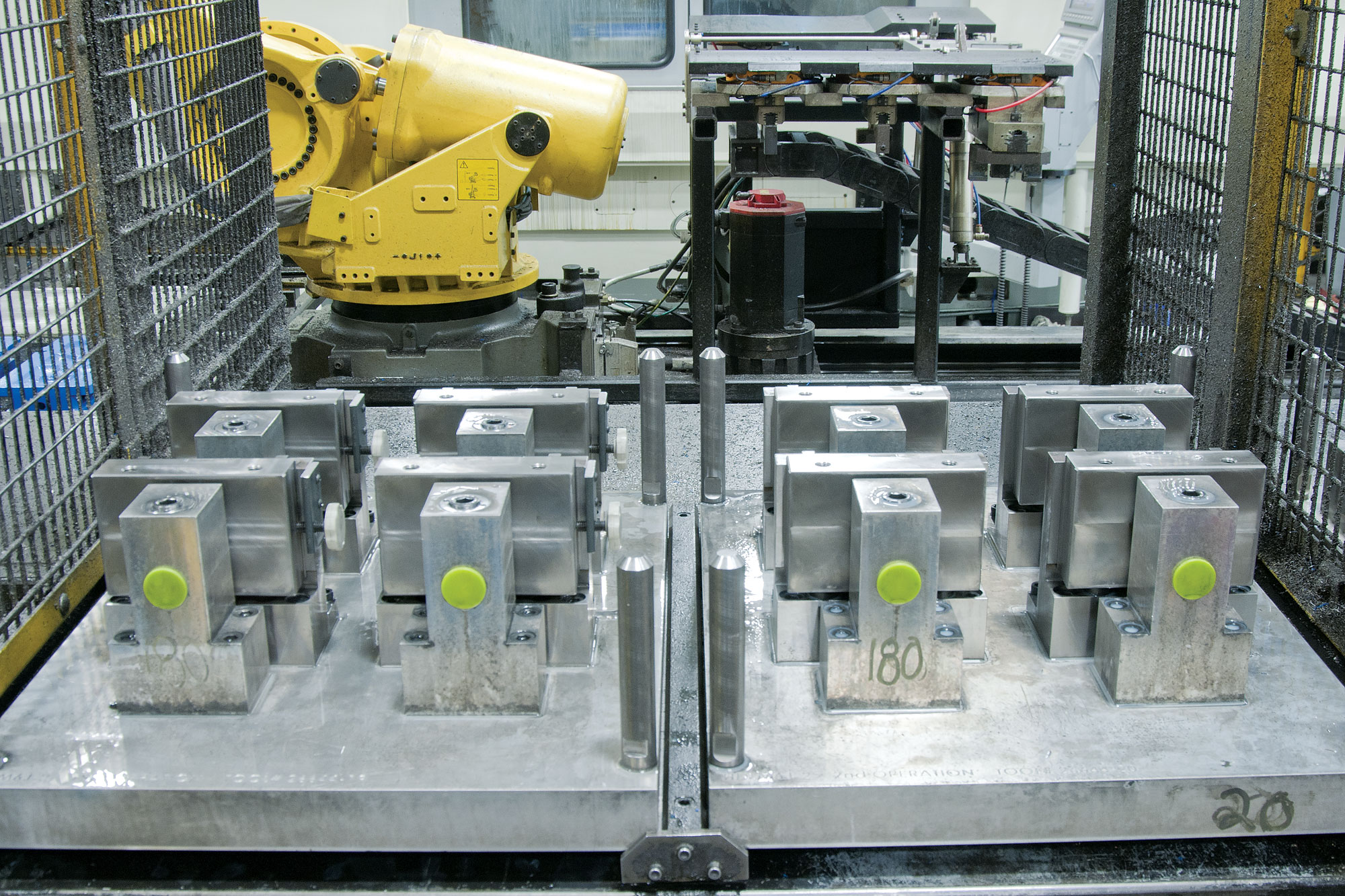

Solution: Kurt serrated Double Station vise towers on palletized machining centers for 24/7 production.

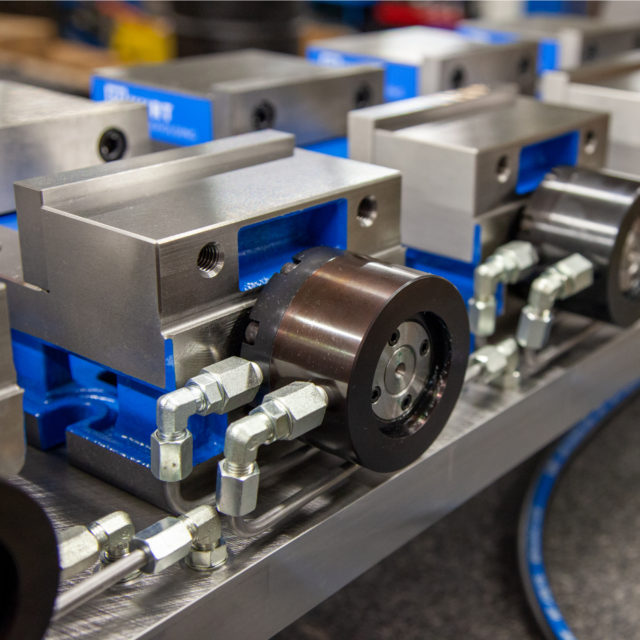

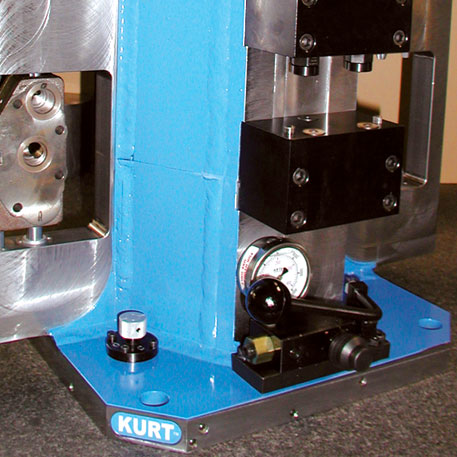

Solution: Window hydraulic (AB Load) fixture allows matching on five sides.

Solution: Multiple towers with DoubleLock vises on palletized machining center for 24/7 production.

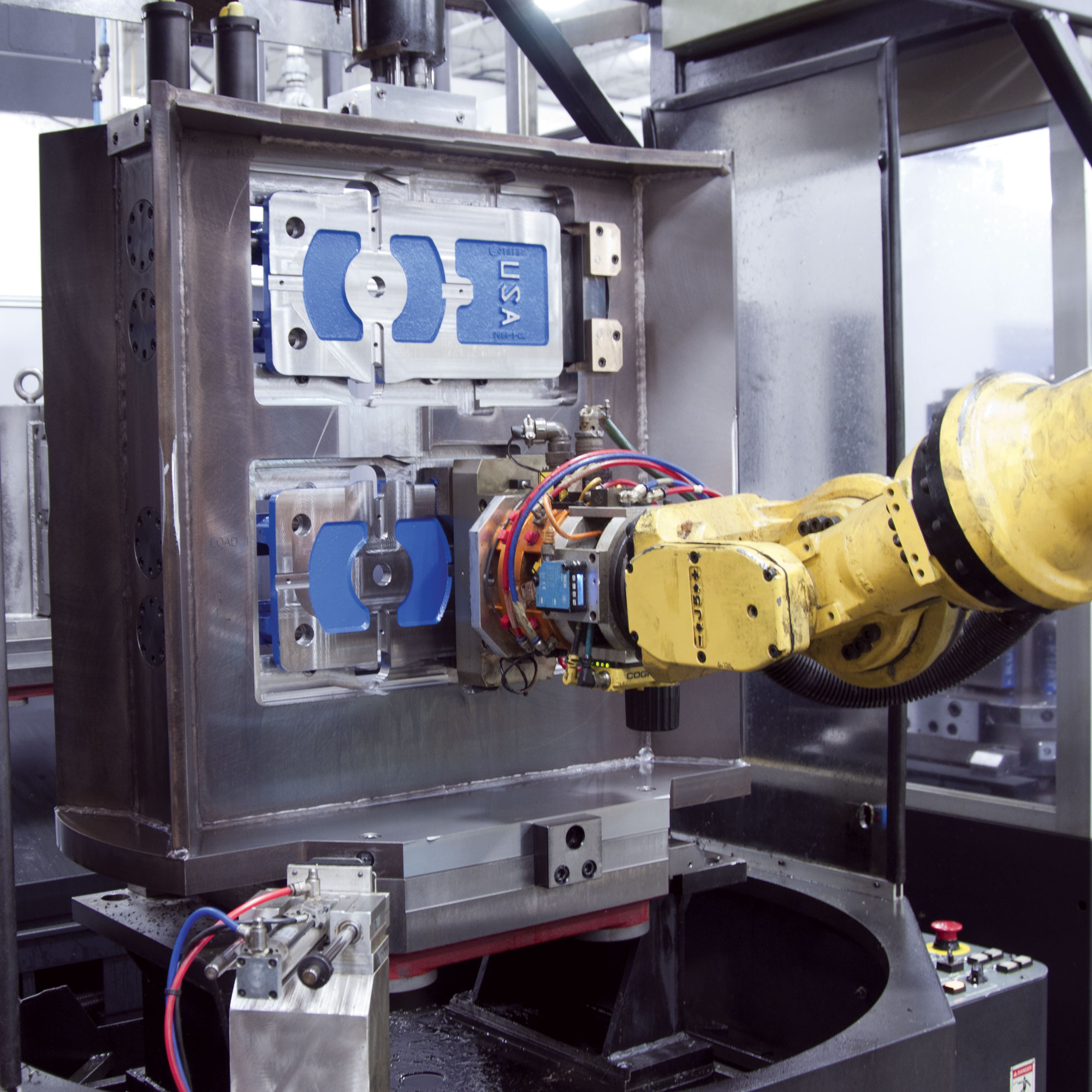

Solution: Window fixture for 2 sided machining enhances automated FMS line.

Explore Kurt’s Custom Workholding Solutions for Vertical CNC Systems

Kurt is proud to provide many of the nation’s top manufacturers with custom workholding products for vertical CNC machining centers.

Examples of our custom solutions:

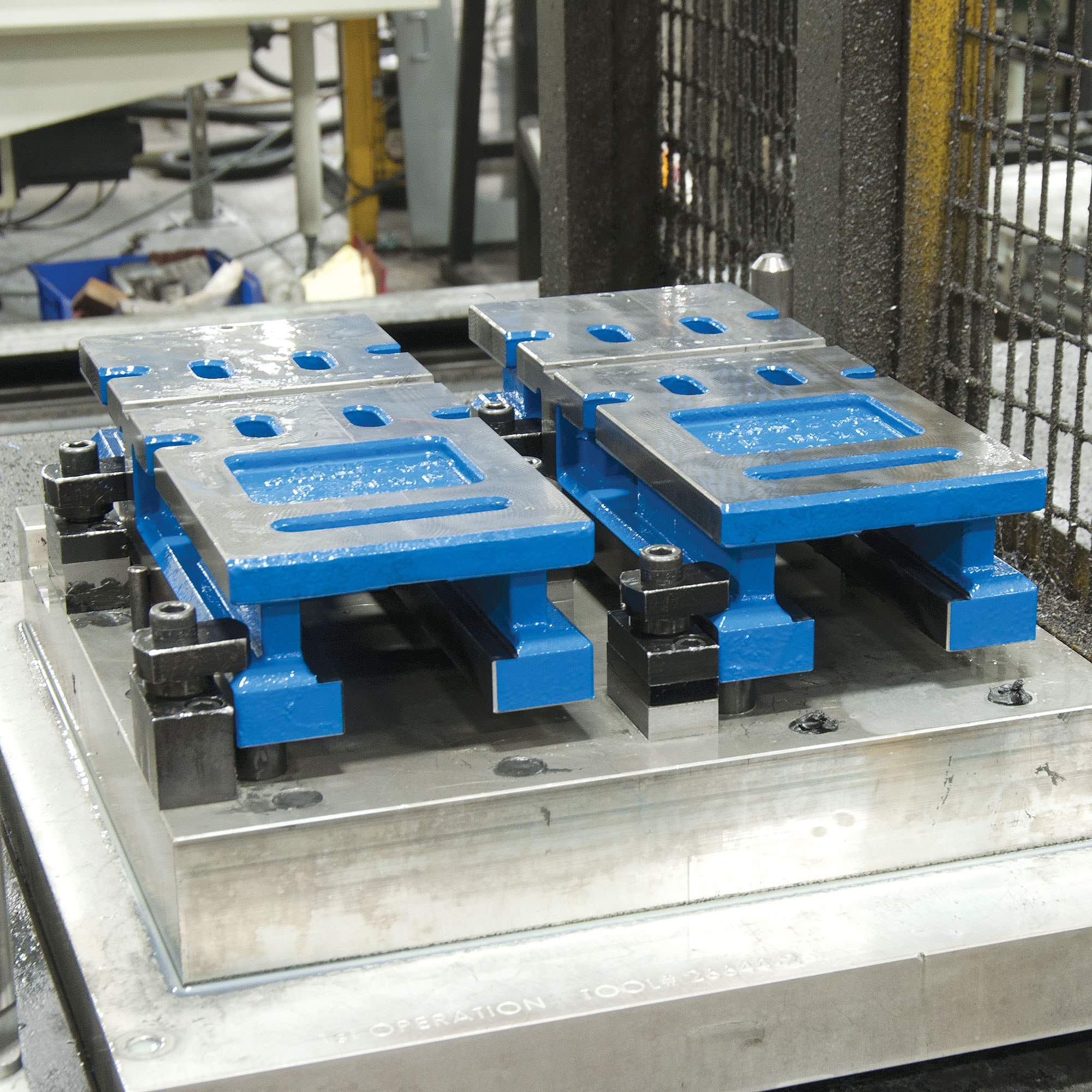

- High-density fixture clamping to accommodate four workpieces per station for hydraulic industry manufacturing

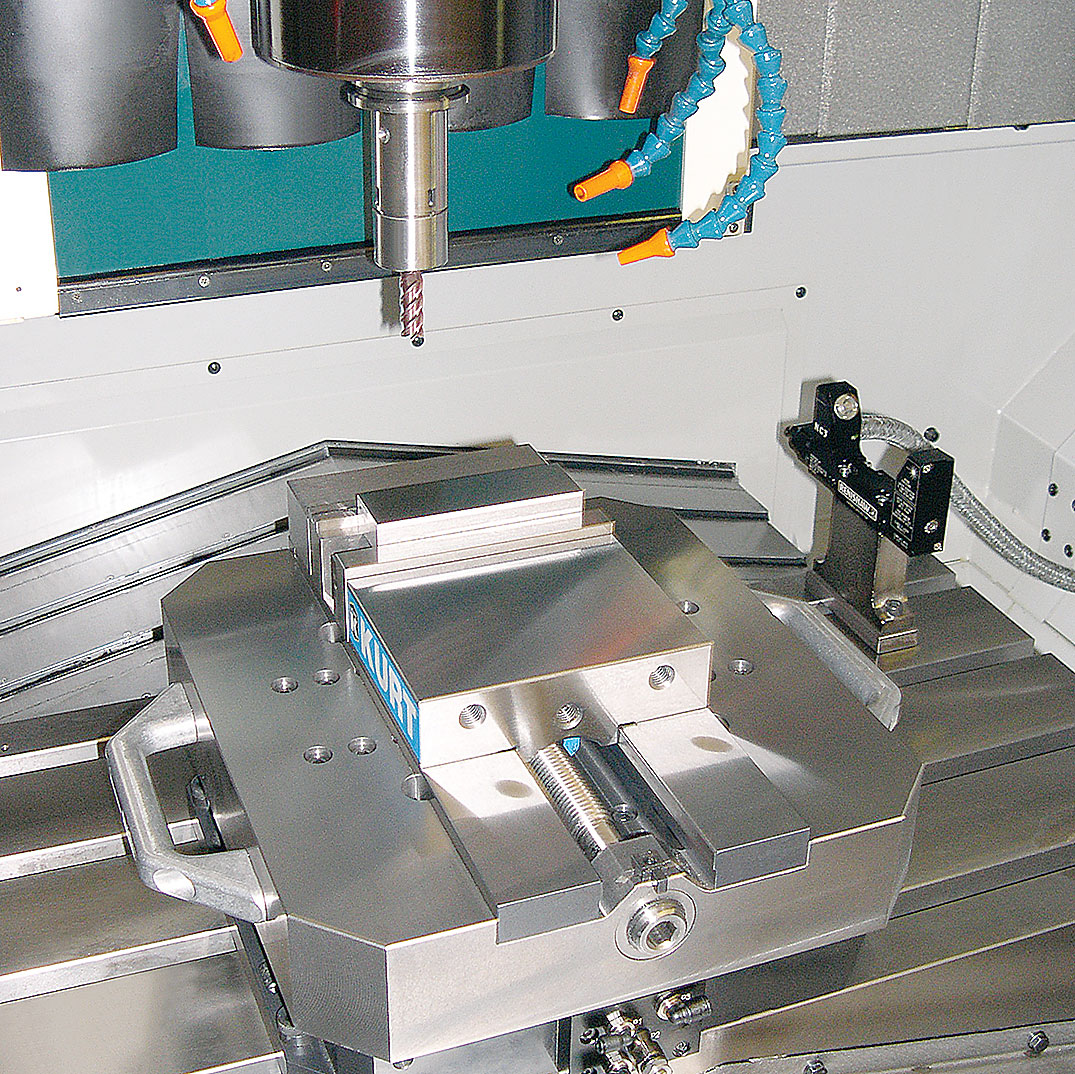

- Custom ClusterLock pallet vises that significantly enhances throughput for a medical device manufacturer

- An indexing trunnion fixture that allows for three-sided machining in automotive applications and countless other customized vises and workholding solutions

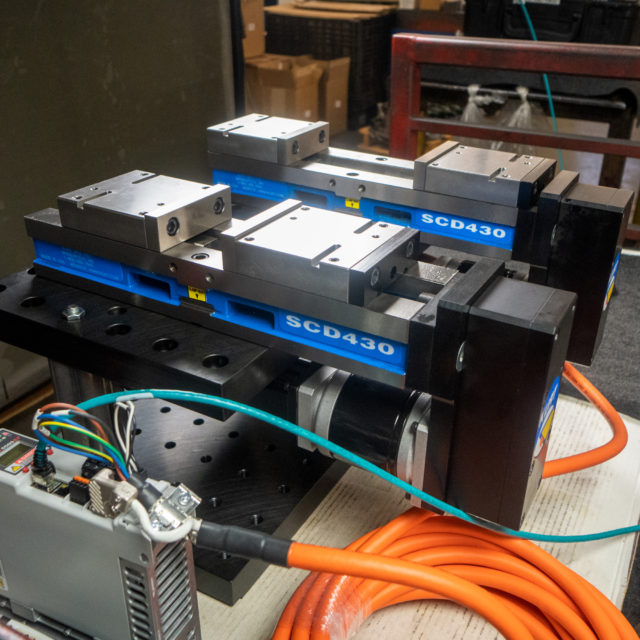

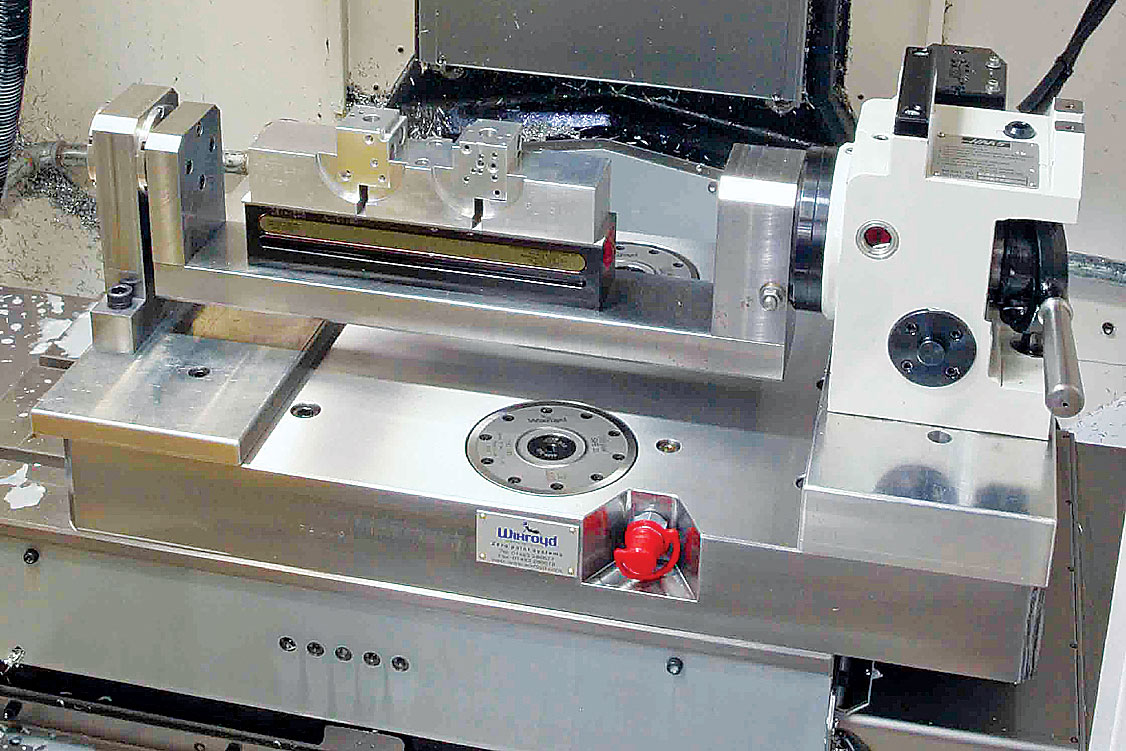

Solution: Rotary table fixtured with a zero-point docking system for repeatability.

Solution: Up to three-sided machining using an indexing trunnion fixture.

Solution: Eight station indexing trunnion fixture for high speed machining.

Solution: Second operation grinding fixture feeds productivity into FMS.

Solution: Grinding fixture increases holding power and improves accuracy.

Solution: High density fixture clamping four parts per station.

Solution: Custom pallet vise enhances VMC throughput for Device manufacturer.