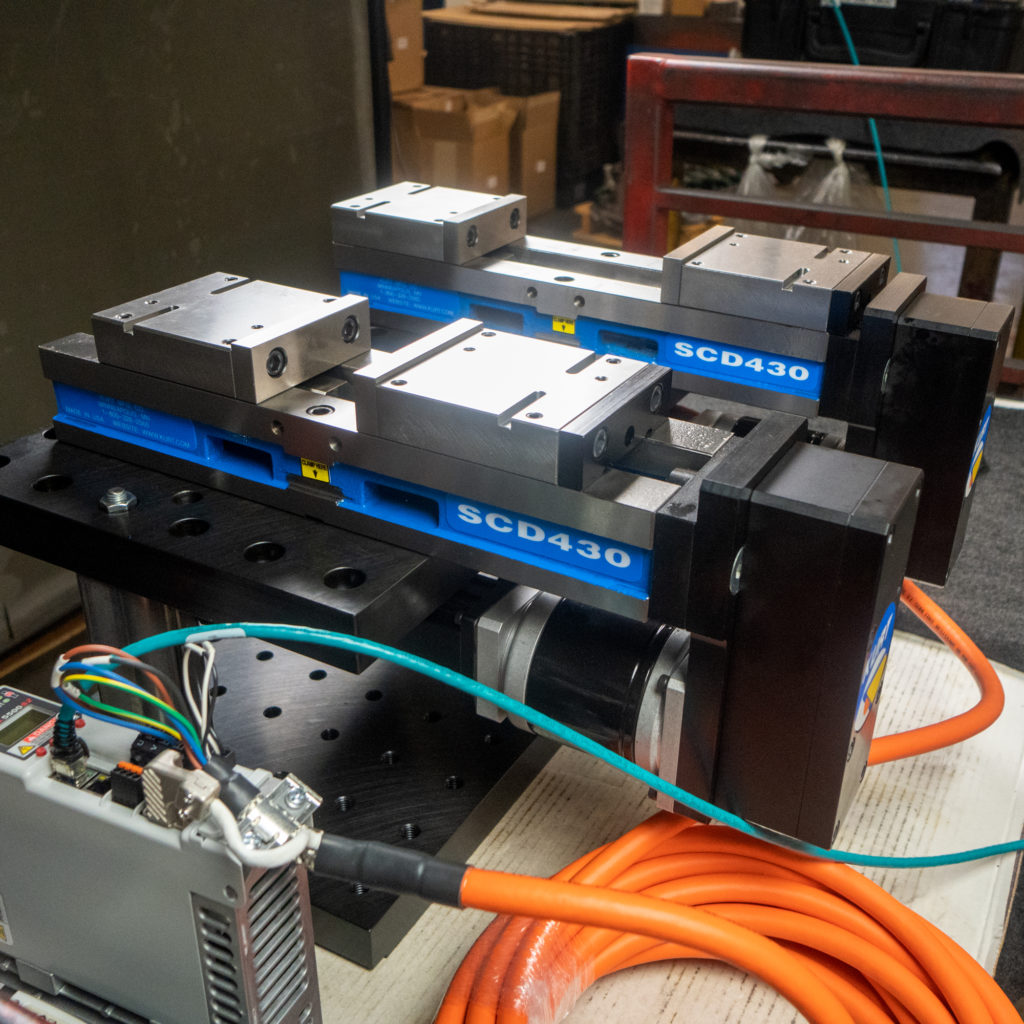

Kurt Custom Engineered Workholding showcases a new dual-vise setup for automated workflow.

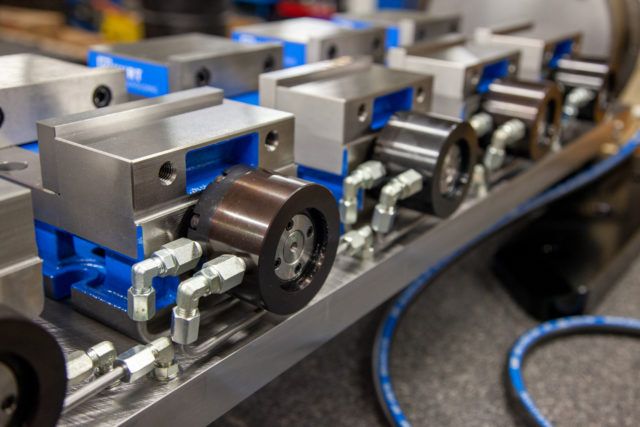

Designing and creating custom engineered workholding is one of our strengths here at Kurt Workholding. We’ve created custom solutions for horizontal and vertical CNC systems ranging from high-density, DoubleLock vise setups capable of holding 18 parts for aerospace machining operations to indexing trunnion fixtures that allows for three-sided machining in automotive applications and countless other customized vises and workholding solutions.

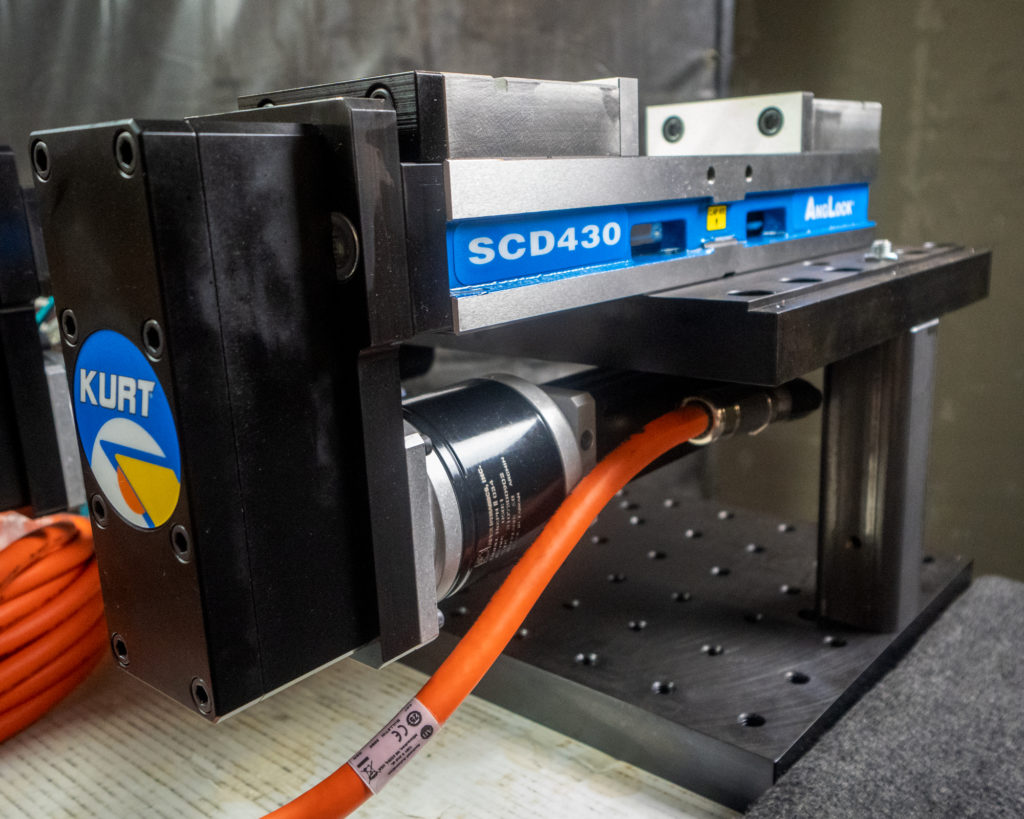

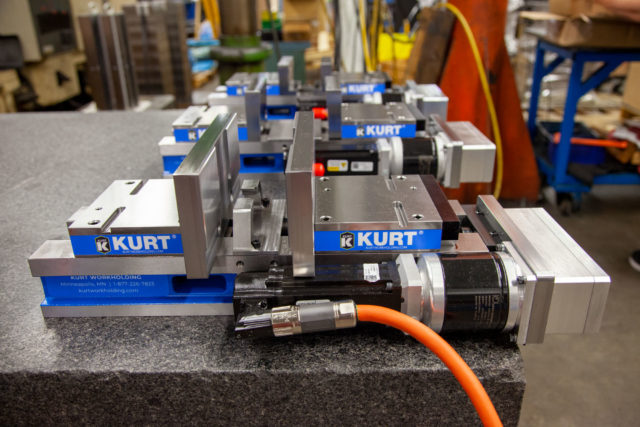

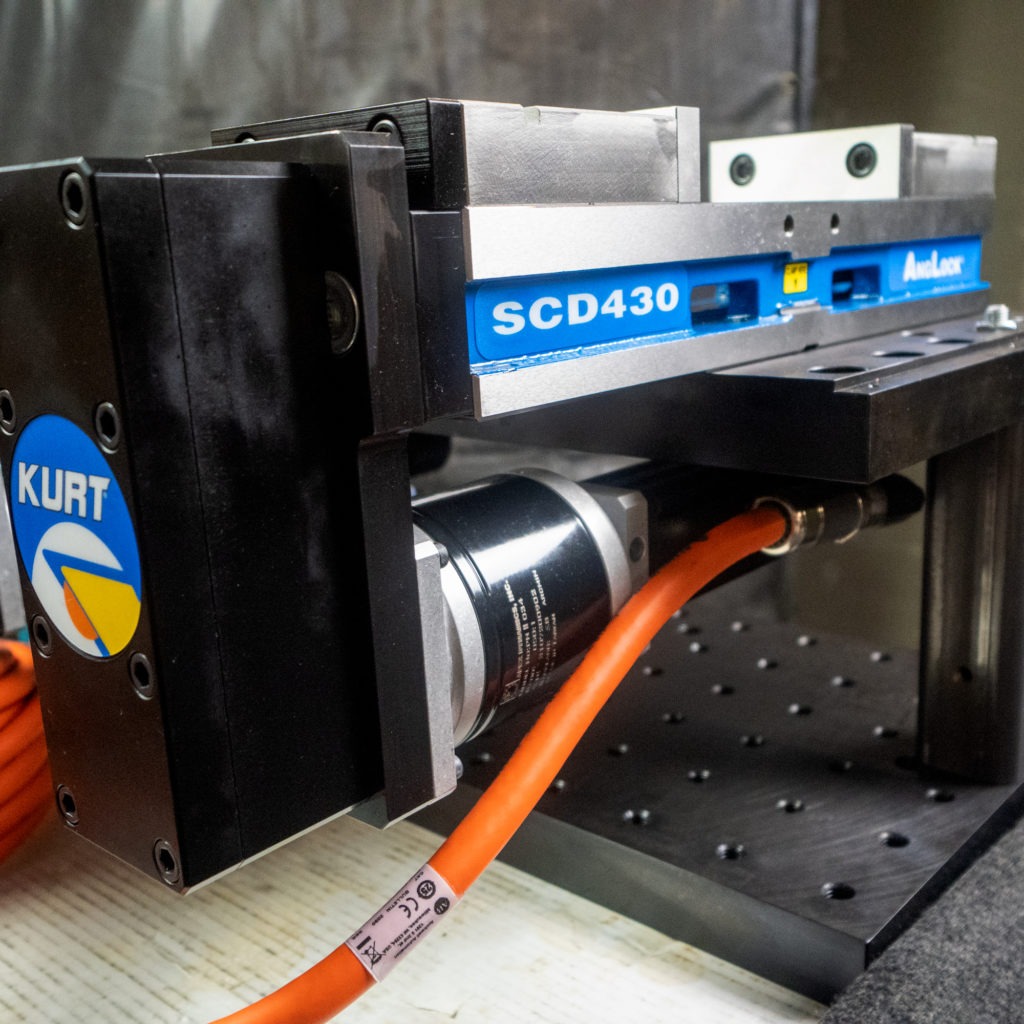

One of our latest creations is a servo-drive setup featuring two Kurt SCD430 self-centering vises actuated by a pair of Kinetix 5500 (Allen Bradley) servo motors controlled by a CompactLogix ERM or ControlLogix controller. Studio 5000 V33 software runs everything.

Servo motors make sense because they allow much more granular control and I/O options including speed, torque and position outputs. The vises are programmed to open to a part width and then another 1/16” to allow the robot to load. Then the vise will close via the servo to stall at a preset torque. The torque preset translates to a given force via the direct linear relationship between torque and poundal force with our vises.

Servos also allows engineers to program a closed width for the part and a width slightly smaller than the part. This allows the machine to cycle off if there is no part in the vise and it hits the close width limit—kind of a poor man’s sensor if you will.

“When automating jaw opening and closing, servos are great for providing accurate high-resolution direct feedback for jaw position and motion.”

Click on the video to see the vise in action —>

Why we used servo motors for this application:

- Servos allow more control fine tuning vise torque and clamping force needed to securely hold a part. This is especially important in a “light touch” application where you might deform or damage a part if the vise jaws come in too fast or with too much force.

- Servos are great for providing accurate high-resolution direct feedback for jaw position and motion when automating jaw open and close. Servos allow programmers to know that the jaw position is where they expect it to be—accurately and repeatably every time on each part cycle for a reliable vise automation system.

- Servos offer a lot of bang for the buck, achieving higher power output in a compact motor.

- Eliminating hydraulic or pneumatic lines in the machining environment helps clean up the setup and reduce clutter and maintenance around the milling machine.

- These motors also easily integrate into a control system that manages the machine-robot-workholding relationship including handshaking protocols and ladder logic—making for a more turn-key and easy-to-program setup for the end customer.

- Finally, we find that servo motors perform well in a shop environment where they run quieter than hydraulic and pneumatic setups, are better sealed from debris and aren’t susceptible to line contamination by dirty shop air or other issues associated with supply lines.

If you’re interested in applying a similar automation system to a custom engineered workholding application or learning how we can streamline an automated workflow, we’d love to help you out. We can build virtually anything imaginable.

Send us some project details and we’ll get back to you with the solution that’s right for your budget and your application.