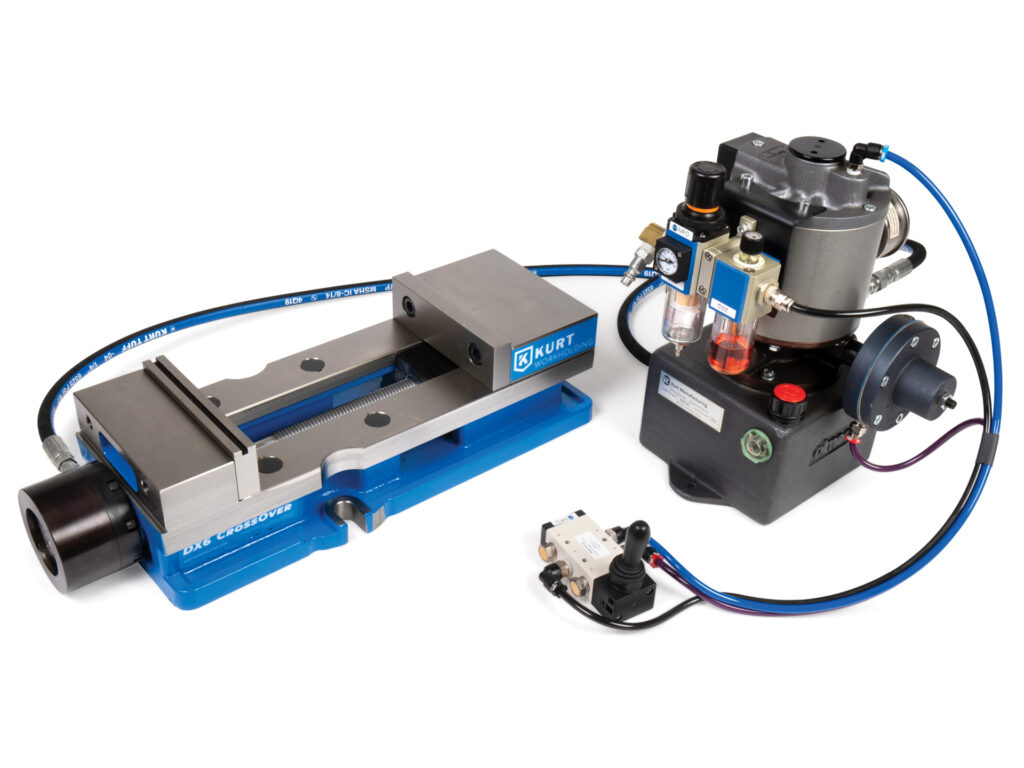

Kurt offers several turnkey solutions for hydraulic workholding automation. With any of our Hydraulic vises, a KHP3 pump and a length of Kurt Tuff hydraulic hose, you can have a single-acting system up and running in your machine.

Benefits of hydraulic automation

Kurt hydraulic automation is an affordable way to improve part holding accuracy and reliability. Our lean hydraulic automation solutions are also flexible and allow systems to be set up to open and close vises with or without an operator present. Kurt hydraulic automation is a high ROI investment.

Hydraulic Automation Is:

- Affordable: It’s affordable, you can have a hand-toggled or foot-switched DX6H system in your machine for right around $3700.

- Accurate: Hydraulic clamping allows precise force on parts, helping to minimize operator variables like experience or hand clamping strength. Controlled clamping force also helps prevent part deformation on more sensitive materials or parts.

- Flexible: Kurt hydraulic workholding systems can be right-sized for a shop. A single KHP3 pump can run multiple vises with a few small add-on parts and accessories. Talk to our Custom Engineered experts and we’ll help you dial in the perfect system.

- Easy to extend: If you invest in a hydraulic automation setup now, it’s easy to add onto it in the future, either with additional vises or even an entirely different setup like on of our hydraulic towers. You’ll have the pump and vises and Kurt Tuff hose working in your shop as long as you expect from Kurt excellence!

See a Fully-Automated Kurt Hydraulic Vise and KHP3 in Action

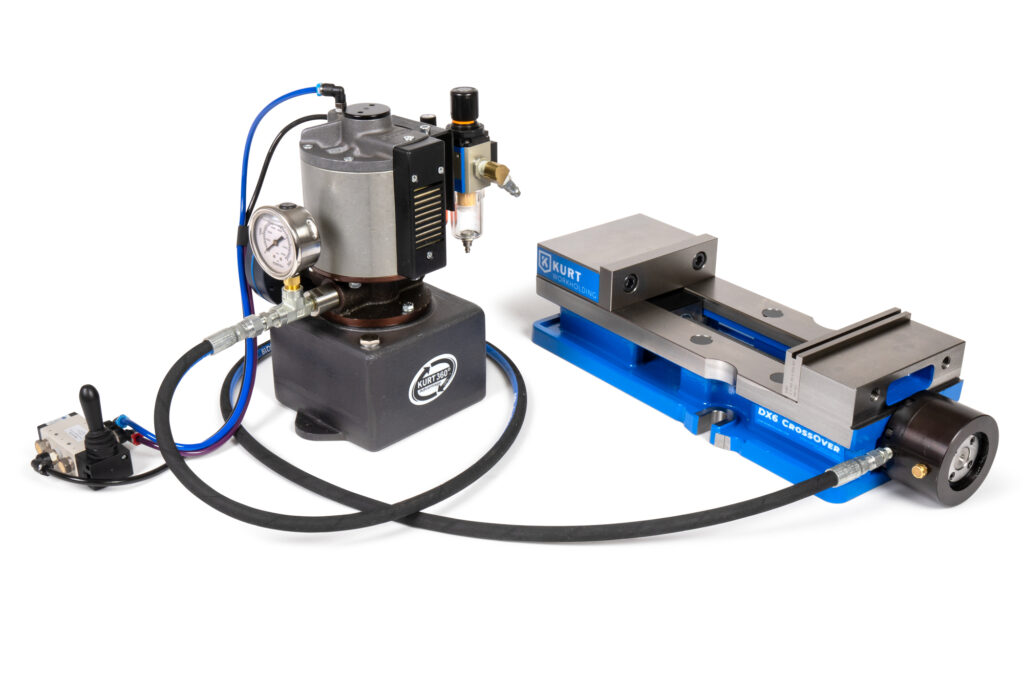

The Kurt KHP3T Hydraulic Pump and Kurt DX6H Hydraulic Vise are the perfect pair for automated workholding actuation. Our Custom Engineered Workholding team can help you configure your CNC center automation setups. We can recommend the appropriate Kurt hydraulic vise, hydraulic pump and connectors designed to fit your specific CNC controller or other I/O device. With additional hydraulic hose assemblies, manifolds, solenoid valves, pressure switches and wire harnesses, a Kurt KHP3 pump can be configured for up to 4 or more vises.

What’s involved?

Our entry-level option is a semi-automated, single-acting solution—meaning that the vise clamps using hydraulic pressure and releases using spring pressure from the vise itself. A system can include any of our hydraulic vises or towers, plus the KHP3 pump configuration of your choice and a length of Kurt Tuff hydraulic hose.

If you need the vise to open and close using hydraulic pressure, you’ll need to configure a double-acting setup using the same parts as the single-acting setup with the addition of a manifold and another length of Kurt Tuff hose.

Both single-acting and double-acting clamping can be controlled remotely with a toggle, hand switch or foot switch. They can also be controlled by a robot, PLC or machine tool controller with additional parts including solenoids and manifolds for fully-automated setups.

Kurt offers a complete line of hydraulic actuated options for single and double station vises as well as 8-station cluster towers. Kurt hydraulic vises are the ideal solution for machining centers that work on long production runs. Hydraulic vises integrated into machining centers can substantially increase productivity and reduce errors.

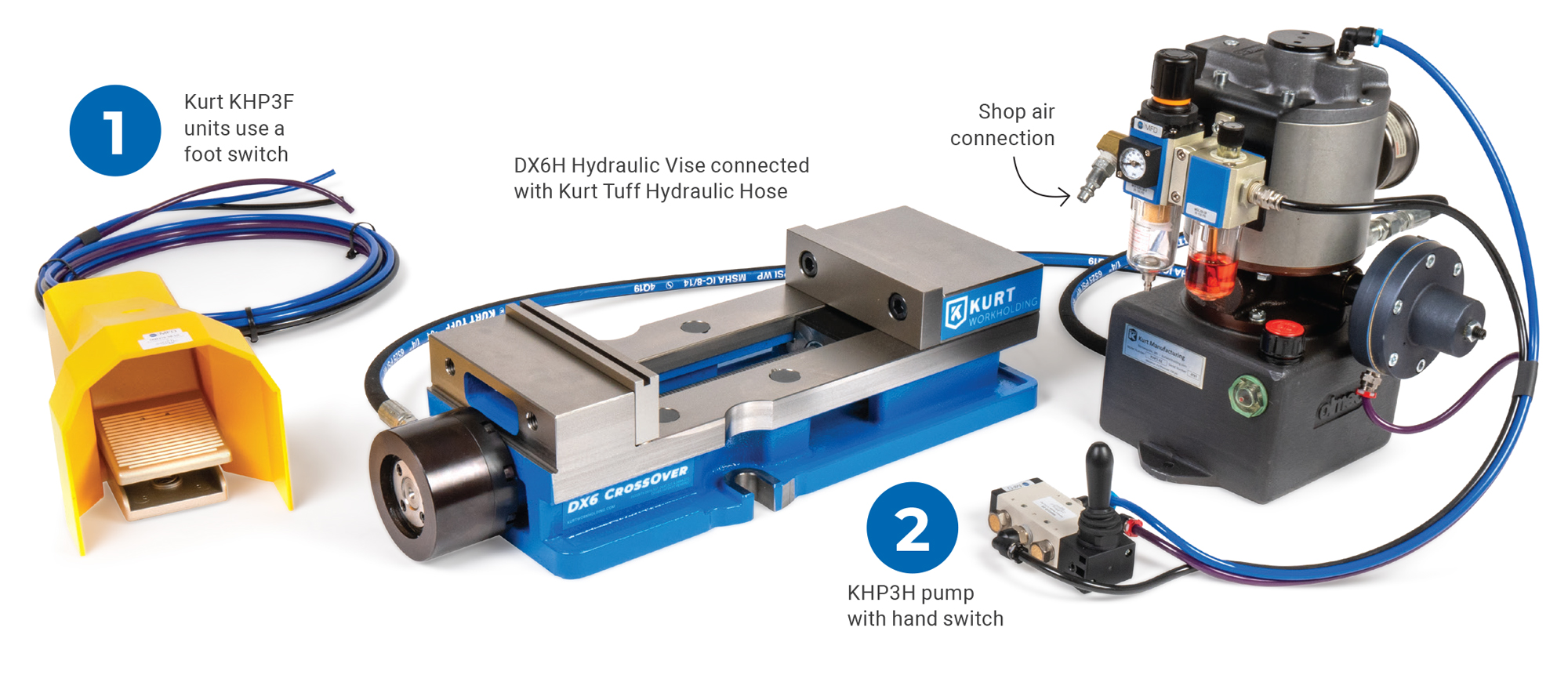

Kurt KHP3 pumps, our best-selling air-over-hydraulic models, operate with shop air and can be configured as single- or double-acting and run from one vise or multiple vises on a single pump. Pumps operate semi-automated with an operator controlling the pump using a foot switch (KHP3F), hand switch (KHP3H) or a toggle (KHP3T). KHP3 pumps can also be configured to run fully automated using a machine tool controller, robot or PLC.

3 DXH Hydraulic Vise Automation Options

Kurt currently offers 3 turn-key solutions for automating our hydraulic vises. Each of the options is a semi-automated setup and requires an operator at the switch. Any of Kurt’s hydraulic vise options will work with this configuration including the VersatileLock series, Double Station vises and hydraulic Cluster Towers.

- Hand toggle switch for remote operation

- Foot switch for remote operation.

- Actuate using an on-pump switch. (not shown)

Key Features: Kurt Hydraulic Vises

- Hydraulic actuation works using shop air and the KHP air-over-hydraulic pump.

- Can be set up as single acting or double acting.

- 1/4-inch hydraulic stroke.

- Choose from multiple Kurt hydraulic vise models.

- Flexible system can start with a single vise on one pump and add more vises as needed on a single switching system.

- Easy to fully automate with additional parts including: solenoids and a DIN cable connected to a machine tool controller, PLC or a robot.

- New DXH Hydraulic models are affordable and offer a lower barrier to entry into automation without compromising on quality.

- Hydraulic screw kits are also available as an upgrade for newer DX vise models.

Affordable and easy to integrate

Hydraulic-vise automation using Kurt’s turnkey system maximizes ROI and takes the guess work out of automation. New DXH Hydraulic vises offer an attractive price point in 4-inch, 6-inch and 8-inch sizes. Any shop interested in integrating vise automation can be up and running with minimal investment since a hydraulic setup only requires the vise, shop air, a length of Kurt Tuff hydraulic hose and a few fittings—it’s an affordable, straightforward option.

Shops who already own newer DX vises also have the option to upgrade their vises using the The DX6H Hydraulic Screw Upgrade Kit, available as an upgrade conversion kit for shops that may already have a few DX6 vises inside machines.

Automate a Hydraulic Vise with a Pump and a Hose

Need a fully-automated air or hydraulic workholding setup? Contact our Custom Engineered Workholding group today!

Kurt does this all the time. We can create a very simple or a very complex system. Kurt also offers fully-automated hydraulic-vise and pneumatic-vise solutions through the Kurt Custom Engineered Workholding group. Just contact CEW directly and tell us about your workholding application and we can design a solution using a machine tool controller, a PLC, a robot and more.