The Kurt DX6A Pneumatic Vise is part of our new automated DX vise series. The new air vise shares many of the same great features of Kurt’s DX6 CrossOver vise with the addition of pneumatic actuation—allowing the vise to open and close using shop air. The DX6A introduces premium air-actuation to our most popular 6-inch vise platform and provides shops with an affordable turn-key automation option for consistent clamping and better finished parts. The vise can be set up semi-automated—to operate manually from the built-in lever or from a remote mounted foot or hand switch—or it can be set up fully-automated using a pneumatic solenoid and DIN cable.

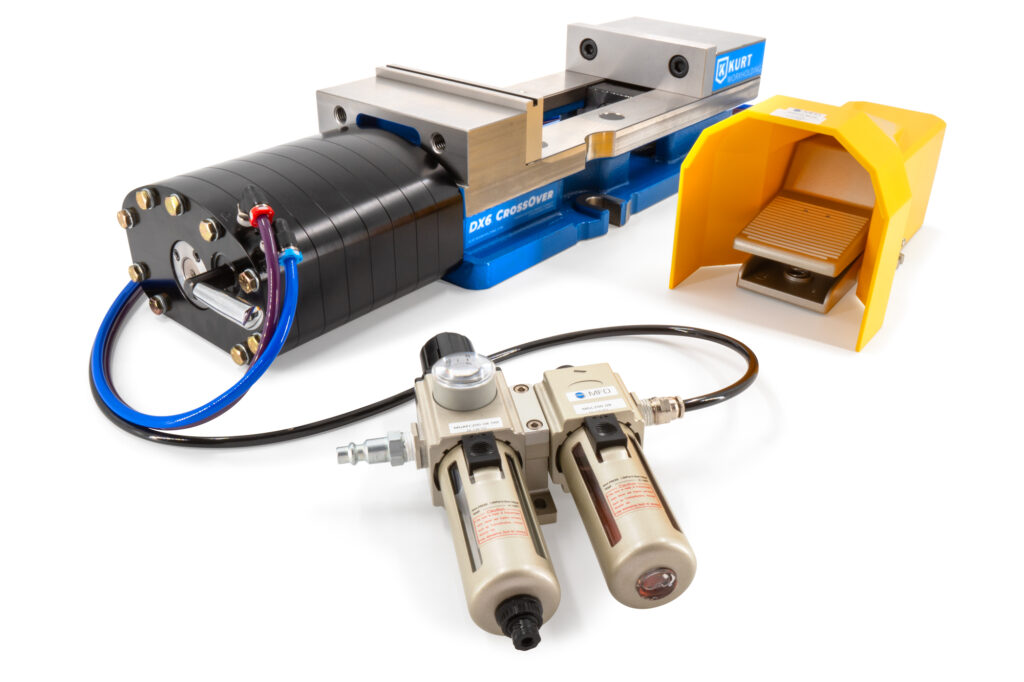

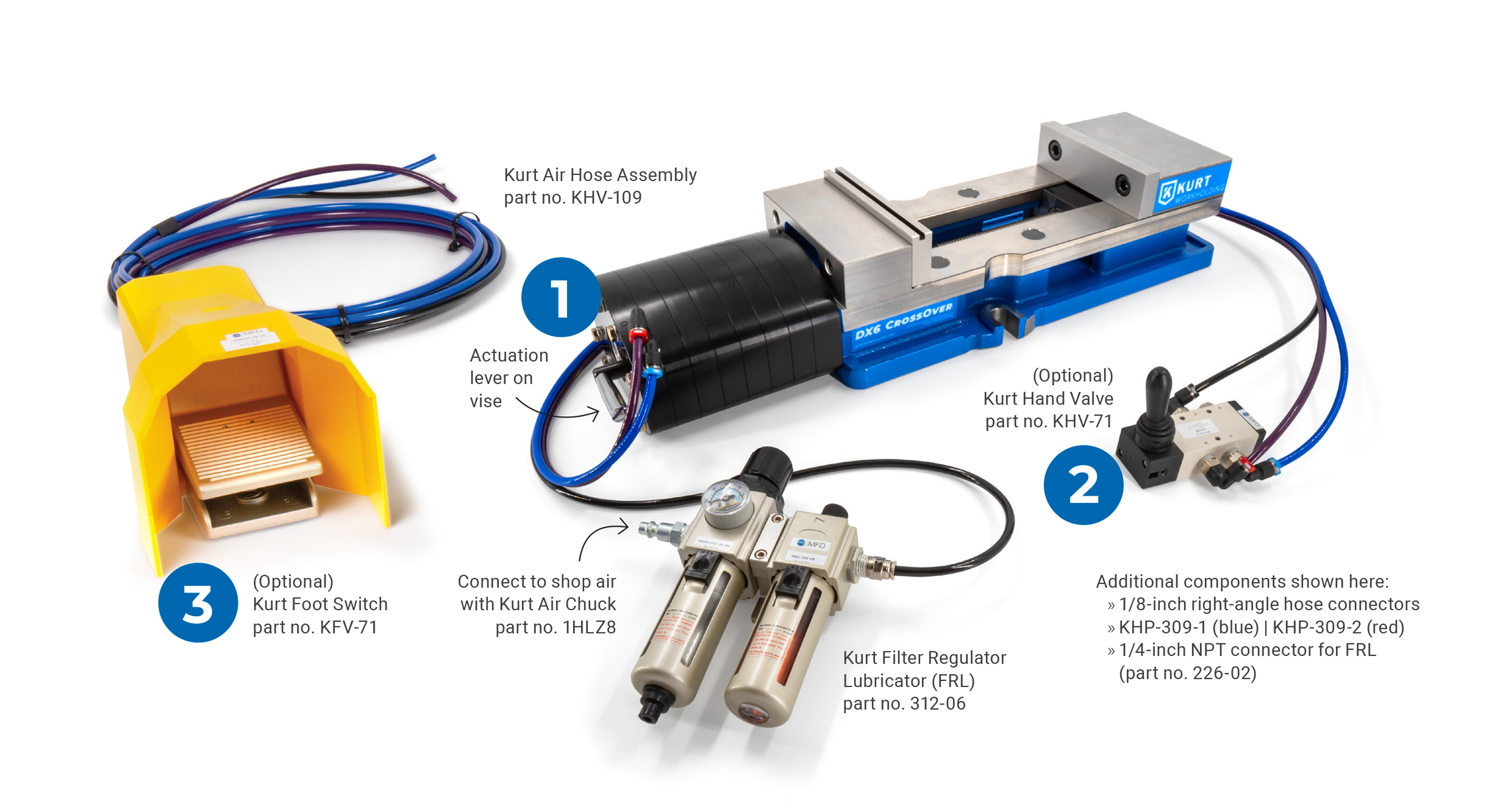

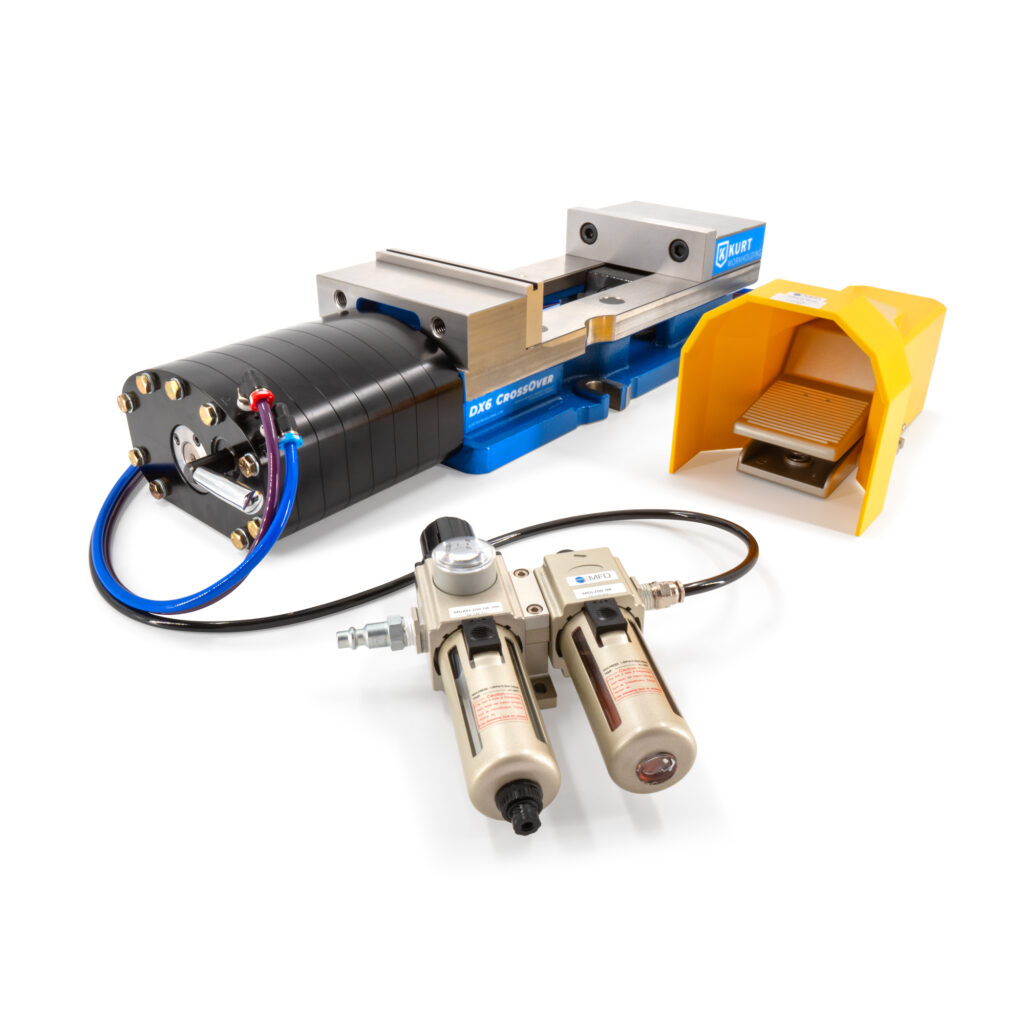

3 Semi-Automated DX6A Pneumatic Setups

DX6A Pneumatic Vise Automation Options

Kurt currently offers 3 turn-key solutions for automating our pneumatic vises. Each of the options is considered a semi-automated setup and requires an operator to open and close the vise.

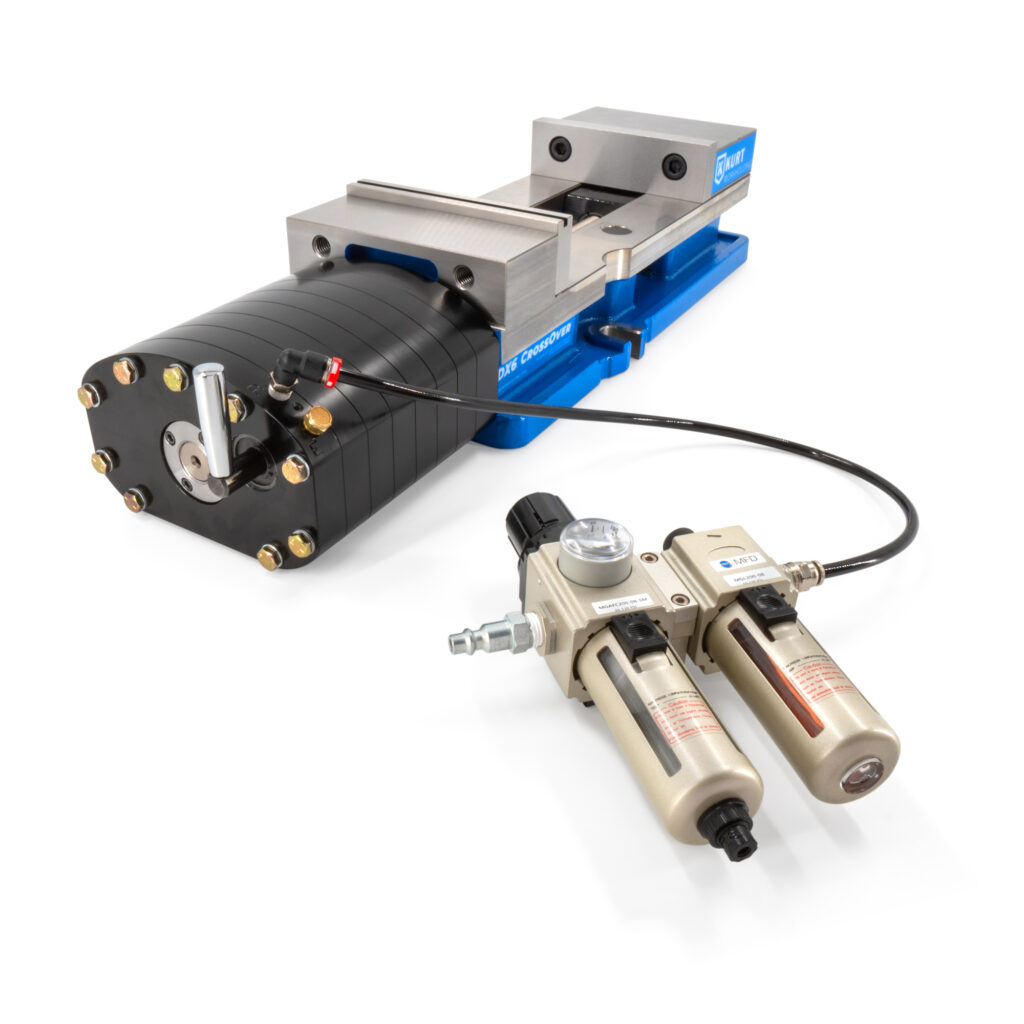

- Actuate using the on-vise lever with shop air running through a Kurt FRL.

- Add an optional foot switch between the FRL and vise for remote operation.

- Add an optional hand switch between the FRL and vise for remote operation.

DX6A Key Features

- Pneumatic actuation works using shop air.

- Double-acting air unit design opens vise and closes vise with air pressure.

- 1/4-inch pneumatic stroke.

- 6-inch jaw width with up to 9 inches of opening.

- Manually actuate vise with built-in lever or remotely with an optional switches.

- Fully automate with addition of a solenoid and DIN cable connected to a machine tool controller, PLC or robot.

- DX vise body design with cast stationary jaw provides more stability and less deflection.

- New lower-profile air unit.

- Pneumatic screw kit also available as an upgrade for newer DX vise models.

Kurt also offers fully-automated air-vise solutions through the Kurt Custom Engineered Workholding group. Just contact CEW directly and tell us about your workholding scenario and we can design a solution using a machine tool controller, a PLC, a robot and more.

There’s often a Creative Workaround

Here’s a unique solution to the rule that a semi-automated setup requires an operator to open and close the vise: if your shop can use a robotic end effector to open and close the vise inside the machine as this video demonstrates at :42 seconds.

Affordable and easy to integrate

Pneumatic-vise automation is the easiest and most basic solution for a shop interested in integrating vise automation. Since an air setup only requires the vise, shop air, an FRL, a length of air hose and a couple of press fittings, it’s an affordable and straightforward option. The DX6 pneumatic unit is also available as an upgrade conversion kit for shops that may already have a few DX6 vises inside machines.

Parts and Accessories to Automate a Pneumatic Vise

For all vise setups, you’ll need clean, lubricated air held at a steady pressure so we recommend using a Kurt Filter Regulator Lubricator – FRL between the shop air connection and the vise and any switches to ensure the best-quality air is coming into the unit at the desired operating pressure.

Semi-automated, operator actuated setups require only shop air, a Kurt FRL, air hose and a few fittings. An optional foot switch or hand switch can be added between the FRL and vise for remote manual operation.

Fully-automated, machine tool controller, PLC or robot actuated setups can be configured by adding a pneumatic solenoid and a DIN cable. Contact Kurt Custom Engineered Workholding directly for help designing a fully-automated system.